Zambelli LFT 30 S/F shrink wrapper

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Interested in the ad?

1/10

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Price:

on request

Ask for price

Contact the seller

Brand:

Zambelli

Model:

LFT 30 S/F

Type:

shrink wrapper

Year of manufacture:

2008

Running hours:

2,000 m/h

Net weight:

4,500 kg

Location:

Italy (Verona) - Italy7231 km from you

Italy (Verona) - Italy7231 km from you

Placed on:

more than 1 month

Seller stock ID:

FA35

Condition

Condition:

used

Remote inspection

Vehicle delivery service

Important

This offer is for guidance only. Please request more precise information from the seller.

Purchase tips

Seller's contacts

Subscribe to seller

Languages:

English, French, Russian, German, Italian, Spanish, Hungarian

Languages:

English, French, Russian, German, Italian, Spanish, Hungarian

Address

Italy, Veneto, 37022, (Verona) - Italy, via Incisa 1, 37022 Fumane

Seller's local time:

15:58 (CET)

Send message

Seller's contacts

Used Bottling Lines

Italy

Italy

1 year at Machineryline

4.3

12 reviews

Subscribe to seller

+39 340 227...

Show

+39 340 227 2376

+39 392 456...

Show

+39 392 456 1373

+39 344 035...

Show

+39 344 035 4270

Ask the seller

PDF

Share

Facebook

WhatsApp

Viber

Telegram

Selling machinery or vehicles?

You can do it with us!

Similar ads

price on request

2004

Power

81.58 HP (59.96 kW)

Contact the seller

price on request

Contact the seller

price on request

Contact the seller

price on request

Contact the seller

price on request

Contact the seller

price on request

2009

Power

36.05 HP (26.5 kW)

Contact the seller

Used Shrink Wrapper Zambelli LFT 30 S/F

Manufacturer: ZAMBELLI, Italia – 2008.

Model: LFT 30

Capacity: 30 packs/min

Working hours: only 2,100

Packer is for PET bottles only 1.5 – 2.0 – 2.5 l (packs 3×2)

Not for smaller bottle volumes

Packaging with foil without pad

The machine is still connected.

Preserved in good condition.

General Description

Machine for packaging in heat-retractable material, continuous movement, no sealers,

Latest generation for medium and high production levels.

Maximum speed depending on machine model type of product and bundle to be formed

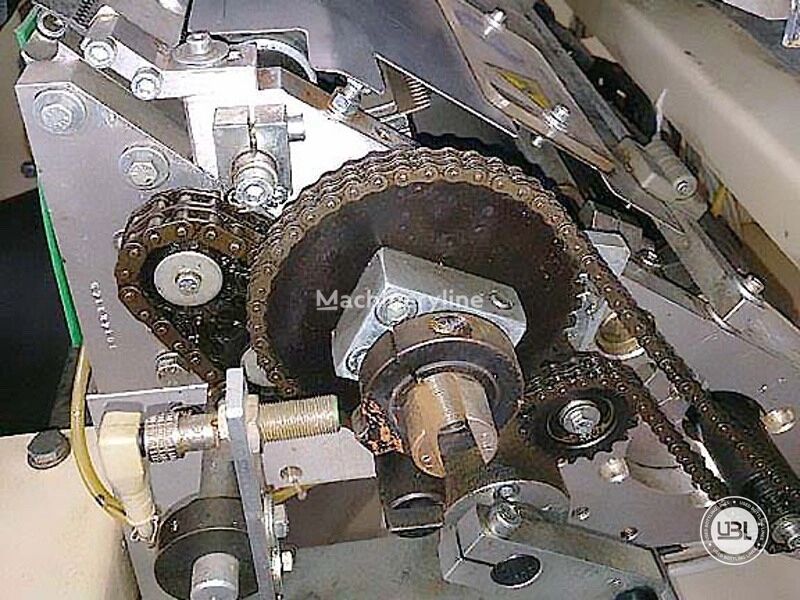

Unique design features in this type of machine:

no mechanical parts on the operator side, thus giving great accessibility.

mechanical parts grouped on opposite side to operator, thus making all routine and

non-routine maintenance jobs simpler and faster.

Used Shrink Wrapper

Great range of choice, both in formats and versions.

Simple and very quick format change.

Electronic film unwinding and cutting.

Film cutting with rotating blade.

Usable film thickness from 40μ to 80μ.

Possibility of using large reel size giving maximum working autonomy.

The whole machine functions are supervised and controlled by a Zambelli computer.

Machine complete with all safeguards, in accordance with current safety regulations.

All machine configurations with possibility of working on a number of tracks.

Vast range of optionals, including: computer for production data processing, antistatic bar, print registration, etc.

The computer is particularly useful in that it can also be used for the careful planning of the machine’s preventive maintenance schedules.

The controls are centrally grouped on an on-board control panel.

All the motors are protected with automatic magnetothermal switches.

Special care has been taken in the design stage to ensure that the machine is simple to run, with easy access for maintenance work.

All the mechanical parts are grouped on the opposite side to the operator, for the following reasons:

a) To allow access to the product with the minimum number of obstacles.

b) To give maximum access for all routine and non-routine maintenance jobs, making them as quick and easy as possible.

c) To simplify enormously all operations on the product conveyor belts, especially belt changing operations.

OPERATIVE FLOW LFT 30 S/F

The products reach the machine with the help of a feed belt positioned in line with the outfeed. A proper device divides up the required number of rows into the infeed guides.

A sensor upstream of the feed controls the quantity of product. If the quantity of incoming falls below the minimum set level, the machine will slowly decelerate and stop.

If the product is present, the machine will start again slowly, in automatic, and will go to the maximum set speed with the store full and at constant arrival speed.

This is kept in step and separated by groups by an electronic separation and a conveyor belt with crossbars.

This system will ensure the maximal stability of the product during the translation on the tape, phase carrying the products up to the wrapping station.

The film is unwound by two rollers driven by a motor, dispensing the quantity of film necessary for the wrapping of the bundle.

The cut is made with a rotating blade.

Final stage

As the entire unit is electronically controlled, the pulling and cutting actions are perfectly coordinated with the arrival of the bundles, independently of the running speed of the machine.

When the product has passed completely through the film outfeed zone, the bundle wrapping cross-bar starts to follow the product, pulling with it the tail of the film.

In the final stage of the wrapping process, the remaining tail of the film is taken by the crossbar to beneath the line of the conveyor belt emerging from the wrapping area.

The part of the film extending under the product feed plane is taken over the leading end of the film with the forward movement of the bundle; so that the bundle is completely wrapped.

At the machine outfeed, there is a tunnel on a double supporting frame with mesh sheets.

As the bundle passes through the tunnel, jets of hot air shrink the film and seal the overlap on the bottom.

Technical Data

Overall dimensions see fig. 2.4

Machine body + electrical cabinet weight 4500 kg

Noise rating (db) see technical documentation (chapter 11)

Power supply voltage see internal plate at the electrical panel

Frequency see internal plate at the electrical panel

Installed capacity see internal plate at the electrical panel

Maximum speed 30 cycles/min. (ref. page 2.12)

Operation: electro-mechanical

Machine type: automatic

Operating pressure: 6 BAR

Line colour ivory RAL1015

Product type:

A) 2,0 L and 2,5 L PET Bottles.

SIZE TYPE:

F1 Bottles PET of 2,0 L duopacks;

F2 Bottles PET of 2,5 L duopacks.

Product dimensions

Diameter Height Used Shrink Wrapper

F1 107 338

F2 107 350

Product arrengement and machine speed:

Arrengement Number of rows Machine speed

F1 (2×1) x 3 only film 1 26 – 33 (cycles/min.);

F2 (2×1) x 3 only film 1 22 – 26 (cycles/min.).

Speed: 30 Bundles/minute

Containers: PET

Formats: 1.5 L, 2.5 L

Film type: Neutral

Tray: Not available

Works with printed film: Yes

Machine feed type: Straight

Bundles per minute: 30

Safety features: Yes

Manuals: Yes

stato: Ready for operation