EHT MULTICUT 10-30 guillotine shear

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

plate thickness 10,0 mm

thickness at "Niro-steel" 6,0 mm

cutting angle adjustment 0,5 - 2,5 °

cutting gap adjustment 0,05 - 1,0 mm

back stop - adjustable 10 - 1000 mm

adjustment speed 180 mm/s

down holder 14 Stück

strokes per minute 12 - 25

oil volume 300 Liter

0 max. 300 bar

voltage 400 V

main drive 18,5 kW

weight of the machine ca. 10.000 kg.

dimensions of the machine ca. 4080 x 2350 x 2060 mm

** maintained condition (!!)

** was serviced annually by the manufacturer TRUMPF / EHT

Furnishing:

- Baffle-guided metal sheet shears with automatic cutting angle adjustment

- Machine frame is an all-steel welded construction

* Side stands are connected to the machine table

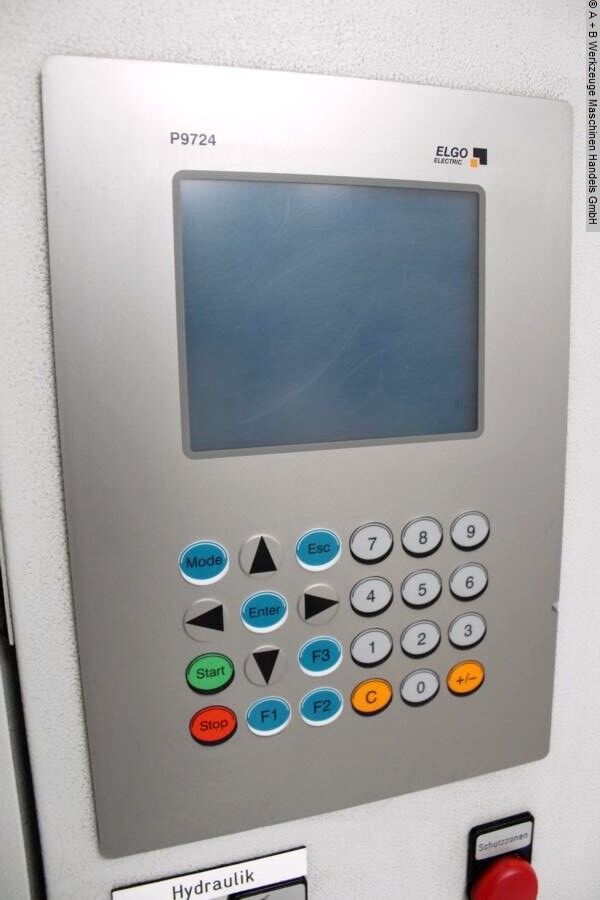

- EHT / ELGO CNC control model P-9724, front left control panel

* for backgauge adjustment and program selection (4 axes)

- Automatic cutting angle adjustment

- Automatic cutting gap adjustment

- Automatic cutting gap compensation

- Support table with ball rollers

* There are recessed grips between the table sheets

- front, hinged finger protection

- hydraulically acting sheet metal hold-down devices

- rear protective device (protective grille + light barriers)

- 1x freely movable foot switch

- original operating instructions

**Special accessories included:

- 1x EHT extra long side stop with mm scale + feet

- 1x EHT extra long support arm with mm scale + feet

- 2x EHT additional support arms with mm scale

* Machine link:

show contacts

The data for this ad was created with ModulMWS - the software solution of LogoTech oHG.

Schnittspaltverstellung 0,05 - 1,0 mm

Hinteranschlag - verstellbar 10 - 1000 mm

Verstellgeschwindigkeit 180 mm/s

Hubzahlen pro Minute 12 - 25

Druck max. 300 bar

Betriebsspannung 400 V

Hauptmotor 18,5 kW

Maschinengewicht ca. 10.000 kg.

Raumbedarf ca. 4080 x 2350 x 2060 mm